Generational innovation

Thenus australiensis. Moreton Bay bugs. The Bay Lobster. Whatever nomenclature you want to use, there is no doubt that these crustaceans are a much-loved staple of Australian seafood menus. And Australian Bay Lobster Producers (ABLP), based near Chinderah, are at the forefront of ensuring production of this delicacy is sustainable, responsible, innovative and importantly, fulfils demand.

ABLP’s strong focus on sustainability is behind the company’s cutting-edge approach to land-based aquaculture biotechnology. And what exactly, you might ask, is that?

“There are a few different types of common aquaculture operations in Australia,” says James Dalton, ABLP manager. “There’s offshore cage aquaculture and onshore ponds, for example, and generally they are open and exposed to the environment.

“We are vastly different in that we’re completely indoors and climate controlled. We use a recirculation aquaculture system, which means that we can reuse as much water as possible by filtering it between our different production areas.”

The story of ABLP’s innovation began in 1994, when James’s father Michael launched the project. Back then, the business was more committed to research and development than the sale of products.

Things are different now. ABLP operates out of a 45-hectare site that will be equipped to produce up to 100kg per day, or 2,000 soft-shell Bay Lobsters, in addition to maintaining a wild caught Bay Lobster operation. The company employs over 50 people.

“The business was founded on the idea that wild resources are limited,” says James. “Michael had been running a business supported by wild fishing, but he had the foresight to develop something on land that was protected from negative externalities. We have such a focus on sustainability – we’re not 100 per cent there yet, and we’re transparent about that, but it’s something we’re working towards.”

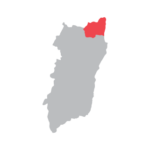

This year (2022) is shaping up to be one of the most important years in ABLP’s illustrious history. The company has started construction of a seawater intake pipeline that will channel fresh seawater from a pipeline offshore from Kingscliff Beach to the ABLP site. James describes the project as “a major milestone that is progressing well”.

“The pipeline will create a large number of jobs for the area and we have a mandate to support local suppliers”

The idea behind the pipeline is primarily to solve the problem of a lack of enough fresh, clean seawater for the company’s operations.

“Just getting to the point where we were allowed to start digging was very difficult,” says James. “But we’re really excited to have started it. Now it’s all about getting it completed, but infrastructure that big is probably going to bring some new challenges as well.

“We undertook a lot of community engagement in the lead-up to the pipeline and it was received quite well. It’s going to create a large number of jobs for the area and we have a mandate to support local suppliers.”

The pipeline, which is set to be finished in the second half of 2022, represents a bright new dawn for ABLP after a COVID-effected couple of years. The company had strong ambitions to expand into international exports, but this idea was swiftly shut down in the wake of the pandemic, due to restrictions and the spiraling cost of freight. But when one door closed another opened.

“We completely refocused on the domestic and local market – on restaurants, as well as adding a direct-to-consumer online platform, selling products to people’s homes, which was initially never on the cards.”

Another string to ABLP’s bow is that it has a number of important partnerships underway, including a research relationship with Griffith University for artificial intelligence and robotics, and one with the University of NSW that focuses on microbiology. The business is truly at the vanguard of innovation in its field.

“ABLP has created and refined a world-first method of rearing Bay Lobster in a commercial aquaculture facility, and created new proprietary biotechnology that can be applied to next generation of food production and waste disposal,” James says.

“We’re looking forward to the next chapter in our history.”

Share this story

Read more stories

overtures of romance and style

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/Osteria-Tweed-Coast.jpg 1000 667 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/Osteria-Tweed-Coast.jpgOsteria

Mark Wilson, Lia Mason and Lee Middendorf all met when the three of them were working in hospitality jobs at The Sandbar …

A community cornerstone bouncing forward

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Coraki-Post-Office.jpeg 2048 1260 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Coraki-Post-Office.jpegCoraki Post Office

For all that has been thrown at the small town of Coraki in recent times, the owners of the town’s post office are rolling with the punches.

Casino RSM Club

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/RMS-Club.jpeg 1360 906 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/RMS-Club.jpegCasino RSM Club

The 23 of March 2020 was the hardest day of Neale Genge’s career.

not just a business, a community partner

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/stone-and-wood-001.jpg 960 761 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/stone-and-wood-001.jpgStone & Wood

“That’s like asking parents to name which of their children they prefer,” says Jamie Cook, Stone & Wood co-founder. He has been asked which of the…

Creativity takes flight

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Honey-Hunt_Jules-Hunt-scaled.jpg 2560 2560 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Honey-Hunt_Jules-Hunt-scaled.jpgHoney Hunt Style

Jules Hunt moved to Byron Bay with her family 15 years ago because she wanted to raise her children with a strong sense of community. It was by chance that this move led to the flourishing of her artistic career – and more recently to her turn as a successful business woman.

world class creatives

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/meme-productions-featured-image.jpg 1000 750 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/meme-productions-featured-image.jpgMememe Productions

The piece of advice that dirtgirlworld creator, Cate McQuillen, likes to share with other creative entrepreneurs in the region tells much about her story…

let’s get physical

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/grafton_physio_business_story_001.jpg 2000 1165 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/grafton_physio_business_story_001.jpgGrafton Physio + Sport

You know you’re in good hands when you visit your physiotherapist and she turns out to be a world-class athlete. That’s the case for those who…

Cool to be kind and cans it

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/The-Kind-Coffee-Co.-Product.jpg 957 1277 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/The-Kind-Coffee-Co.-Product.jpgThe Kind Coffee Co.

The KIND Coffee Co, reflects its name in everything it does.

Keeping it real in the Tweed

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Tweed-Real-Food_Julia-scaled.jpg 1706 2560 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Tweed-Real-Food_Julia-scaled.jpgTweed Real Food

Tweed Real Food is a business launched in 2018 from a desire to be resilient. Little did founder Julia Foyster know how prescient her plan would turn out to be.

following her art’s desires

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Bingara_Angela-Parr-scaled.jpg 2560 2198 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Bingara_Angela-Parr-scaled.jpgBingara Gallery

If she wasn’t painting wild animals and birds, artist Angela Parr, 62, would most likely be rescuing them, healing them, or advocating for them…

flying high, with a helicopter view

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/air-tg-ballina-helicpoters-002.jpg 800 531 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/air-tg-ballina-helicpoters-002.jpgAir T&G

Northern Rivers is well known for its breathtaking natural beauty, and imagine if your day at the office involved enjoying these views from the air…

take me to the river

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/10986182_733888960072606_3561220566688304460_o.jpg 2048 1536 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/04/10986182_733888960072606_3561220566688304460_o.jpgGrafton to Yamba Houseboats

The Clarence River, at the southern end of the Northern Rivers, is known colloquially as the ‘Big River’, while its Aboriginal name is ‘Breimbah’ or…

putting the business into ‘show business’

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Brainstorm-Productions-image2-scaled.jpg 2560 1709 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Brainstorm-Productions-image2-scaled.jpgBrainstorm Productions

You might think that COVID-19 would rattle a business that delivers educational theatre into schools. But the “show must go on” mentality runs deep for Brainstorm Productions’ founder and artistic director Jenny Johnson…

The dream team

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Joel-Jensen_team-photo-scaled.jpg 2560 1707 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Joel-Jensen_team-photo-scaled.jpgJoel Jensen Constructions

Despite the pressures of running an award-winning construction company, there’s one thing Joel Jensen strives to do every day.

Hovering across the wave of success

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/FliteImage.jpg 1139 749 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/FliteImage.jpgFliteboard

It was meant to be an extended break for David Trewern and his family. A chance to rest and reset in Byron Bay after decades of building and selling fast-growing digital marketing agencies. But as he looked out over Belongil beach in 2014, an idea struck him.

Dance call for Kyogle

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Ascent-Dance_group-dancers.jpg 1473 828 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/Ascent-Dance_group-dancers.jpgAscent Dance

Starting a dance school just five weeks before the onset of a pandemic might have dampened the spirits of some new business owners, but Haylee Holliday took it as a sign that Ascent Dance Studio had to succeed.

Generational innovation

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/ABL-2.jpg 1440 1080 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/12/ABL-2.jpgAustralian Bay Lobster Producers

Thenus australiensis. Moreton Bay bugs. The Bay Lobster. Whatever nomenclature you want to use, there is no doubt that these crustaceans are a much-loved staple of Australian seafood menus.

biggy pop sings support for matilda

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Byron-Bay-Wildlife-Hospital-2-scaled.jpg 2048 2560 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2022/11/Byron-Bay-Wildlife-Hospital-2-scaled.jpgByron Bay Wildlife Hospital

In 2020, Iggy Pop received a Lifetime Achievement Award at the Grammys; in the same year his pet cockatoo, named Biggy Pop, became the founding patron of Byron Wildlife Hospital…

all fired up for global attention

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/03/Aurora-Suspended-Fires_Ballina-in-good-company-image-4.jpg 960 600 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/03/Aurora-Suspended-Fires_Ballina-in-good-company-image-4.jpgAurora Suspended Fires

Aurora Suspended Fires arose from the perfect marriage of Chloe Allan’s creative talents with Neil’s engineering background. But building a successful…

carefully crafted business success

https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/Evans-Head-Cabinetry-001.jpg 2000 1041 In Good Company | Northern Rivers In Good Company | Northern Rivers https://ingoodcompanynorthernrivers.com.au/wp-content/uploads/2018/06/Evans-Head-Cabinetry-001.jpgEvans Head Cabinet Making

“People often say, ‘They don’t build things like they used to’,” says fine furniture and cabinet maker Justin Crisp. “But I can confidently say…”